Bioethanol made from molasses offers a range of benefits that make it an attractive and sustainable alternative to traditional fossil fuels.

Let's explore some of the key advantages of bioethanol produced from molasses:

-

Renewable and Sustainable: Molasses is a byproduct of sugar production, derived from sugarcane. Sugarcane can be cultivated and harvested continuously, making molasses a renewable resource. Unlike fossil fuels, which are finite and depletable, molasses-based bioethanol helps reduce our dependence on non-renewable resources and contributes to a more sustainable energy future.

-

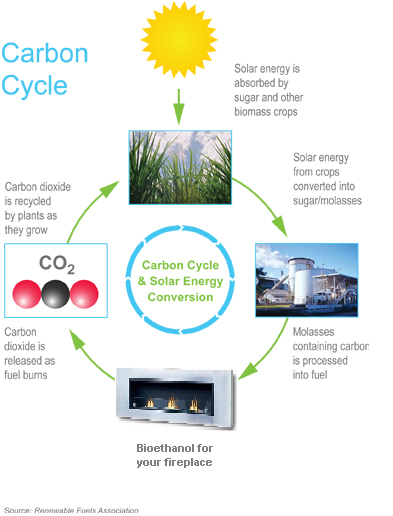

Greenhouse Gas Reduction: Bioethanol derived from molasses is a cleaner-burning fuel compared to gasoline. When combusted, bioethanol produces significantly fewer greenhouse gas emissions, particularly carbon dioxide. The carbon dioxide released during bioethanol combustion is offset by the carbon dioxide absorbed during the growth of the sugarcane or sugar beets used to produce the molasses. This carbon neutrality helps mitigate climate change and reduce the overall carbon footprint.

-

Energy Security and Independence: Bioethanol produced from molasses helps enhance energy security by reducing reliance on imported fossil fuels. By promoting domestic production, countries can lessen their vulnerability to geopolitical uncertainties and fluctuations in oil prices. It provides a reliable and locally available source of energy, contributing to greater energy independence.

-

Waste Utilization: Molasses, which was traditionally considered a waste product in the sugar industry, becomes a valuable feedstock for bioethanol production. By converting this waste into a useful resource, bioethanol production from molasses contributes to efficient waste management. It reduces the environmental impact associated with molasses disposal and minimizes waste accumulation.

-

Economic Benefits: Molasses-based bioethanol production provides an additional revenue stream for the sugar industry. Instead of treating molasses as a waste product, it becomes a valuable commodity, enhancing the profitability and sustainability of sugar mills. The diversification of revenue sources can help stabilize the sugar industry's finances and contribute to the economic growth of sugar-producing regions.

-

Job Creation: The establishment of bioethanol plants and associated infrastructure generates employment opportunities. This job creation is particularly significant in rural areas where sugar production is prevalent. The growth of the bioethanol industry helps stimulate economic activity, improve living standards, and promote local development.

Ethanol, specifically in the form of pharmaceutical-grade ethanol with a purity of 99.9%, plays a crucial role in pharmaceutical manufacturing. Here is a summary of its uses in this industry:

Solvent: Ethanol serves as a versatile solvent in pharmaceutical manufacturing. It is used to dissolve and extract various active pharmaceutical ingredients (APIs) from plant materials, herbs, or other sources. Ethanol’s ability to dissolve a wide range of compounds makes it an essential solvent for the extraction of medicinal compounds.

Sterilization and Disinfection: Ethanol is widely used as a disinfectant and antiseptic agent in the pharmaceutical industry. It effectively kills or inhibits the growth of microorganisms, making it ideal for sanitizing equipment, surfaces, and containers during the manufacturing process. Ethanol’s antimicrobial properties help maintain a sterile environment in pharmaceutical facilities.

Preservative: Ethanol acts as a preservative in pharmaceutical formulations. It is commonly used to stabilize liquid medications, preventing the growth of bacteria, fungi, and other microorganisms. Ethanol’s preservative properties help extend the shelf life of pharmaceutical products and maintain their efficacy over time.

Solvent for API Formulation: Ethanol is utilized as a solvent in the formulation of pharmaceutical products. It aids in the dissolution and homogenous mixing of APIs, excipients, and other components to create liquid formulations such as syrups, suspensions, and tinctures. Ethanol’s ability to solubilize various compounds makes it an essential ingredient in pharmaceutical preparations.

Extraction of Phytochemicals: Ethanol is commonly used to extract phytochemicals from plants in the production of herbal medicines. By soaking plant materials in ethanol, the desired bioactive compounds are extracted, resulting in concentrated extracts used in various pharmaceutical formulations.

Diluent: Ethanol is used as a diluent in the preparation of certain pharmaceutical dosage forms. It can be added to adjust the concentration of active ingredients in liquid formulations, ensuring accurate dosing and enhancing the stability of the product.

Cleaning Agent: Ethanol is employed as a cleaning agent in pharmaceutical manufacturing facilities. It is used to clean equipment, glassware, and utensils, removing residues and contaminants. Ethanol’s high evaporation rate and effectiveness against microorganisms make it an ideal choice for cleaning processes.

How does citronella work in the Bioethanol fireplace?

Bioethanol Fireplace Fuel Citronella repels target pests rather than killing them. It works by masking scents that are attractive to insects. Burning of the fuel in an outdoor firepit releases and creates an invisible barrier of citronella within the general area of the firepit. Insects find this barrier and the smell of citronella unappealing and as a result find it difficult to locate their target to feed. It is also thought that citronella may also work by masking odours attractive to pests. However, this thought has not been confirmed by official scientific study.

What is Citronella Bioethanol Fireplace Fuel?

Citronella is a naturally occuring grass plant originally from central Asia. Citronella oil is removed from the plant by a process called steam distillation. The oil that is removed from the grass is yellow to brown in colour and has a grassy/floral smell. Citronella is a mixture of many components, and the exact composition varies by grass variety. However, the main components are citronellol, citronellal, and geraniol. The components contained within the citronella oil have a unique property that repells insects.

Using the most pure bioethanol and highest quality citronella, this fuel burns with a beautiful yellow/orange flame and a soft hint of citronella. Designed to allow you to entertain your way outside this spring and summer mosquito free.

Ideal for use in all brands of bioethanol firepits.

It is important to realise that not all ethanol is equal, especially when it comes to sustainability.

There has been much debate around use of biofuels taking resources away from food production. This debate mainly refers to the overseas production of ethanol and specifically the use of corn and grains to produce ethanol.

The sugar/molasses based ethanol situation is different, sugar is a sweetener not a food staple. Unlike corn and grain, sugar contains no protein, fat or vitamins.

Other benefits of sugar/molasses based ethanol include:

- The molasses used to produce Ethanol is a by-product of sugar production and is not a “food”

- Ethanol produced from Sugar has 4 times the C02 reduction of ethanol produced from grain.

- 60% of Australian sugarcane is now grown without irrigation.

Water management practices have been implemented by sugarcane farmers through a Rural Water Use Efficiency Project (RWUE). The RWUE project has lead to 91% changing the layout of their farm to improve efficiency of irrigation and/or harvesting operations.

Why should I be concerned if the bioethanol I'm burning contains methanol or hydrocarbons?

Ethanol is exactly the same chemical structure no matter what the feed stock it is products from. However the added denaturants put into ethanol to stop people from drinking the product varies dramatically. These denaturants are not all equal, and burning a bioethanol indoors that contains methanol or petrochemical hydrocarbon is unhealthy and dangerous.

Some companies promote Methylated Spirit or Industrial Methylated Spirit for use in Ethanol Fireplaces. In Australia Methylated Spirit is a technical or industrial grade of ethanol which is denatured with hazardous chemicals for industrial applications and not for burning indoors. The denaturants used in methylated spirit vary and can commonly contain toxic methanol, Methyl Isobutyl Ketone, Denatonium Benzoate (Bitrex) and in hydrocarbons.

Ethanol Fireplace Fuel does not use any of the above denaturants, as they can cause an unwelcome smell when used in ethanol burning fireplaces. Uniquely our bioethanol is denatured with another form of alcohol so that no unwanted smells are given off by the burning fuel. Our Bioethanol Fireplace Fuel is guaranteed methanol, MIBK, Denatonium Benzoate (Bitrex) and hydrocarbon free.

Never use bioethanol that contains toxic methanol, Methyl Isobutyl Ketone, Denatonium Benzoate (Bitrex) and products like kerosene or petrol. Only use bioethanol in your ethanol fireplace.

The biological process of producing bioethanol from either by-products or renewable feedstock makes bioethanol a very green and enviromentally friendly alternative to the petroleum oil, coal and gas based products on the Australian market. A sustainable and renewable fuel.

Bioethanol Fireplace Fuel is made from renewable biological by-products from sugar production. This by-product is known as molasses, and is fermented with water and yeast to produce bioethanol. After fermentation has finished, all solids and water are removed by distillation resulting in pure ethanol. The solid matter left after fermenting can be used as stock food or fertiliser and the water can be recycled or used on crops for irrigation. A large poercentage of bioethanol produced in Australia is made from molasses.

Bioethanol is one of most common biofuels currently available on the market.